Chapter 3: Problems with Traditional Water Automation

What is Traditional Water Automation?

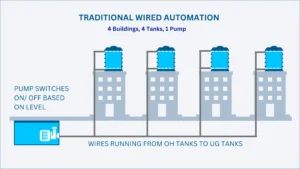

Traditional water automation typically involves a direct wiring setup, where wires run from a tank to a pump. The operation is based on simple on/off logic, such as turning the pump on when the tank is low and off when it’s full. This method relies heavily on physical connections and basic logic circuits. However, it’s becoming outdated compared to modern solutions like an IoT or wireless automatic water pump controller.

For more details about water automation, read- Chapter 1: What is Water Automation?

Problems with Traditional Automation:

-

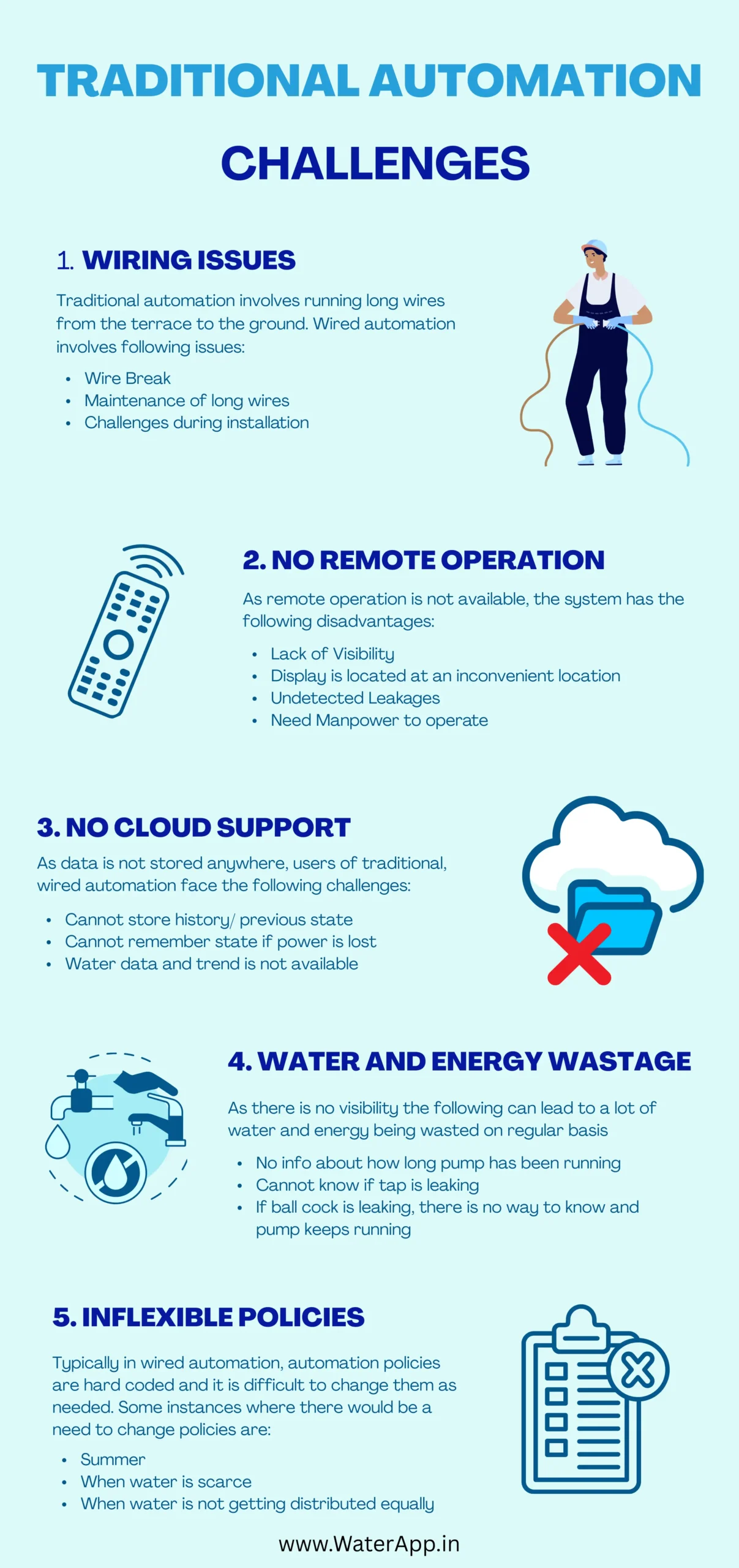

Service Challenges:

Traditional systems often require frequent servicing due to long wires being run from the terrace to the ground. Diagnosing and fixing issues can be time-consuming and difficult, because of the length and quantity of wires. This is where a wireless pump controller could make a difference.

-

Maintenance Issues:

In most of the cases, there is no formal arrangement for maintenance. When anything breaks down, it can be a struggle to find the proper vendor who is available, understands the system and can fix it. In such situations, it is much easier deal with a company rather than a local vendor.

-

Power Interruption:

Traditional systems don’t remember their last state when power is lost. This can lead to problems like the pump not resuming operation as expected when the power comes back. In contrast, an IoT automatic water shut off valve ensures that the system operates efficiently even after power interruptions.

-

Scaling on Sensors:

Over time, sensors in traditional setups can scale, leading to inaccurate readings. Thus, it is very important to have a regular maintenance and service schedule with a responsible vendor.

-

Inflexibility in Policy Changes:

Changing the system’s operational policies, such as adjusting thresholds, is not easy with traditional setups. During hot summer months, people often switch the system to manual mode because the automated settings aren’t flexible enough, leading to inefficiency. However, using IoT pump controllers can offer more adaptability.

-

Messy Wiring:

Traditional water automation involves a lot of physical connections, resulting in messy wiring that can be hard to manage and prone to errors. A wireless system such as level indicators and pump controllers can simplify the setup, reducing the need for extensive wiring.

-

Remote Display Issues:

Typically, the display and control panel are located near the pump, which is not always convenient. Operators need to be physically present to monitor and control the system. An IoT Water Level Indicator can provide real-time monitoring from a distance, making the system easier to manage.

-

Lack of Visibility:

Traditional systems often offer little visibility into their status. For example, you might not know whether the pump has turned on when it’s supposed to. An IoT water tank monitoring and pumping solution can alert you immediately, improving system visibility.

-

Water and Energy Wastage:

Without proper control, the pump may run unnecessarily, wasting both water and energy. This is often due to inadequate feedback mechanisms that don’t stop the pump when it’s no longer needed. An automatic water shut-off valve or automatic water level control valve can prevent such wastage by ensuring the pump only operates when necessary.

-

Undetected Leaks:

Traditional systems usually don’t have the capability to detect leaks, leading to significant water loss over time. An IoT system comes with the power of cloud, data and analytics. Based on historical data and analysis, modern water leak detection systems can quickly identify and address leaks, preventing waste and potential damage.

-

Overworking the Pump:

If the system degrades, the pump may work overtime without anyone noticing. This increases electricity consumption along with the cost of repair and replacement An IoT automatic pump controller can track usage time and efficiency and send an alert in case of degraded performance; thus saving cost.

-

No Remote Operation:

Traditional systems typically depend on a single operator who physically knows the buttons and controls. This makes remote operation impossible and can lead to inefficiencies. With an IoT automatic valve or pump controller, remote operation becomes possible, enhancing efficiency and convenience.

-

Lack of Data:

Traditional water automation systems don’t provide data logging or tracking, making it difficult to analyze performance or make informed decisions. Incorporating devices like an IoT water level indicator or automatic pump controller can generate valuable data, aiding in better system management.

-

No System Visibility:

Without proper visibility, it’s challenging to monitor the system’s performance, leading to issues like unoptimized pump operation, unnoticed faults, and inefficient energy use. Tools such as a IoT water level indicator and controller provide an app which gives greater system visibility, ensuring timely and effective responses.

While traditional water automation has served its purpose, it comes with several challenges in terms of service, maintenance, efficiency, and flexibility. These limitations highlight the need for modern systems like wireless and IoT automatic water pump controllers, automatic water level control valves, and water leak detection systems, which offer better control, visibility, and efficiency.