CHAPTER 8: Types of Valves and What You Can Achieve with Valve Automation

Valves play a critical role in Water Management System, acting as the gatekeepers that control the flow of water. Whether you’re working on a simple home setup or a complex industrial system, understanding the different types of valves and their potential for automation can help you optimize performance and avoid common pitfalls. Let’s explore the various types of valves and how automating them can revolutionize your water management.

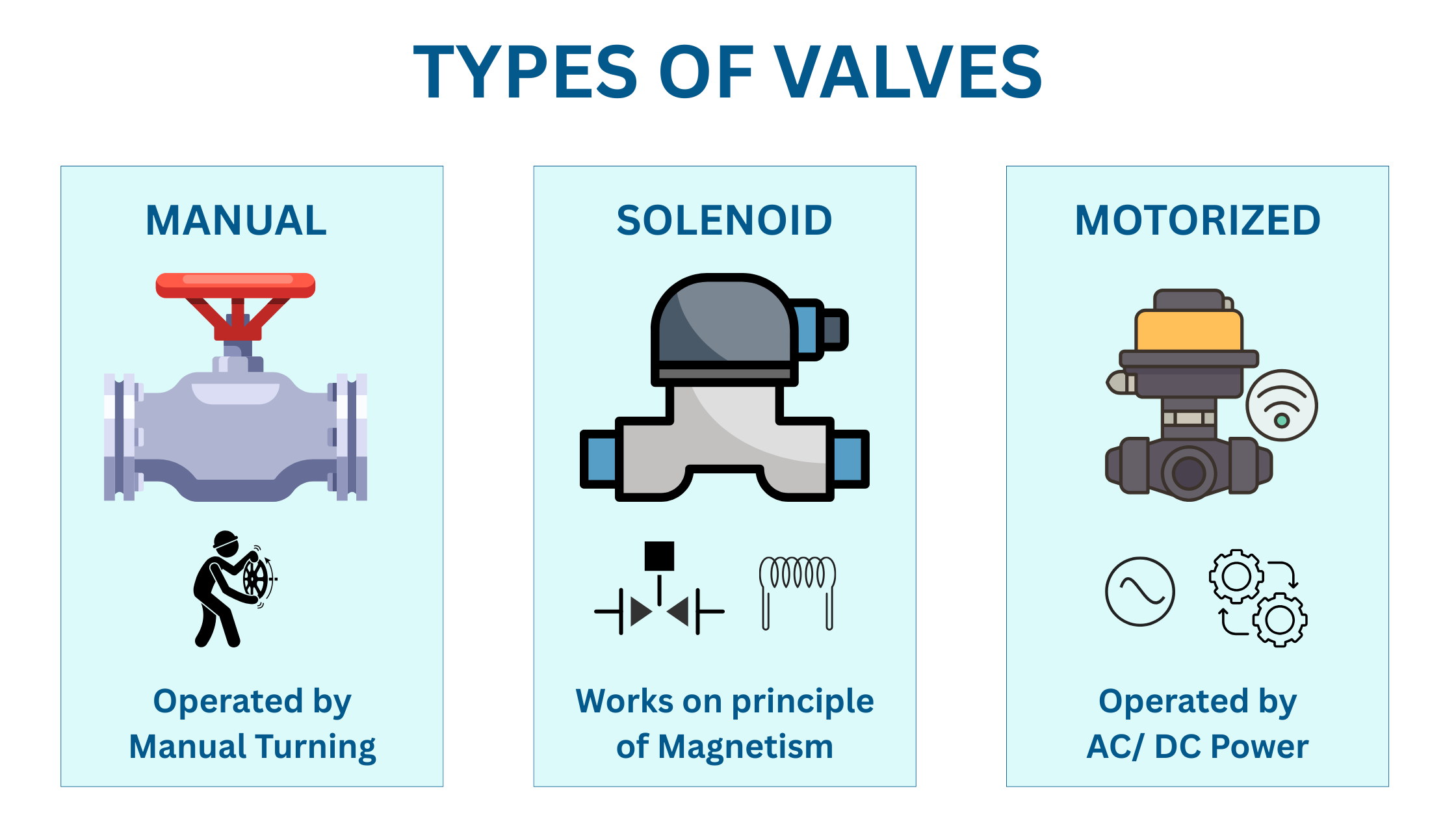

Types of Valves

1. Manual Valves

Description:

Manual valves are the most basic type of valve. They require a human operator to physically turn, lift, or slide the valve to control the water flow. These are often used in simple systems where automation isn’t necessary.

Pros:

- Simplicity: Manual valves are straightforward and easy to operate.

- Cost-Effective: They are usually less expensive than their automated counterparts.

Cons:

- No Automation: Manual valves cannot be automated, which means they’re not suitable for systems that require remote or automatic control.

When to Use:

Manual valves are ideal for small systems or where control needs to be done on-site without the need for automation.

2. Solenoid Valves

Description:

Solenoid valves are electrically operated valves that use a solenoid (an electromagnetic coil) to open or close the valve. They are commonly used in systems that require rapid, frequent control.

Pros:

- Automation Ready: Solenoid valves can be easily integrated into automated systems, making them a popular choice for applications where quick and reliable control is necessary.

Cons:

- Prone to Failures: Solenoid valves can break down easily and are prone to leaks. They often require a bypass pipe circuit in case they get stuck.

- Installation Challenges: Installing a solenoid valve usually requires cutting into the existing pipe, which can be a hassle, especially in established systems.

When to Use:

Solenoid valves are best suited for applications where quick, precise control is needed, such as irrigation systems or in combination with an automatic water pump controller.

Motorized Valves

Description:

Motorized valves are equipped with an electric motor that can be controlled remotely or automatically. These valves are ideal for complex systems that require precise control over water flow.

Pros:

- Highly Automatable: Motorized valves are perfect for integration into automated systems using an automatic valve controller.

- Versatile: They can be programmed to perform various functions, such as diverting water to different tanks or shutting off flow in case of a leak.

Cons:

- Cost: Motorized valves can be more expensive than manual or solenoid valves.

- Complex Installation: Like solenoid valves, motorized valves often require a bypass pipe circuit and pipe cutting for installation.

When to Use:

Motorized valves are ideal for complex systems that need to be integrated with other automated components like an automatic flow control valve or automatic water shut off valve.

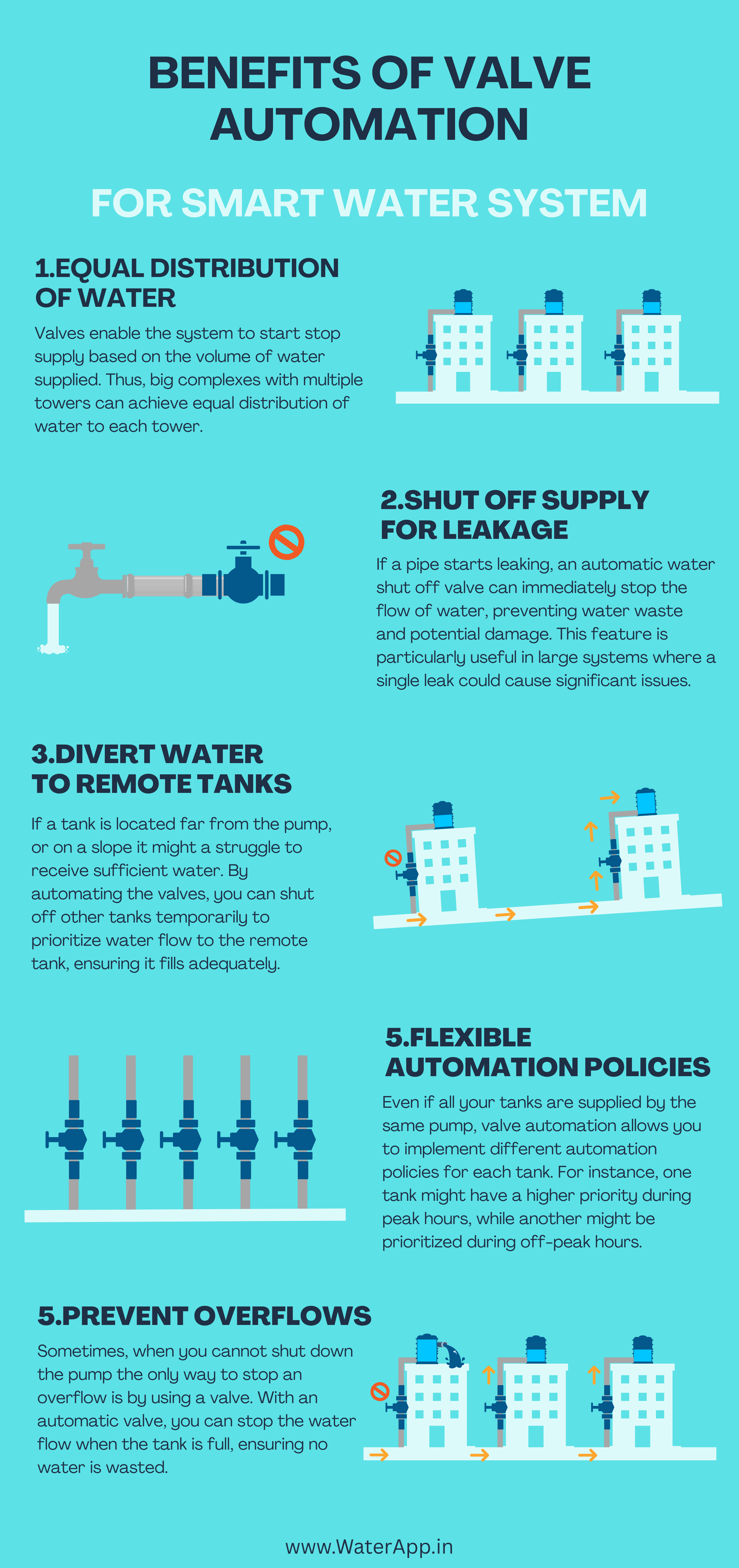

What Can You Achieve with Valve Automation?

Valve automation opens a world of possibilities for managing water systems more efficiently and effectively. Here’s what you can achieve by automating your valves:

- Ensuring all Tanks receive appropriate Volume of Water

Use Case: Imagine you have a single pump that supplies water to multiple tanks across different locations. By automating the valves, you can control the flow of water to each tank, ensuring that all tanks receive the appropriate amount of water based on demand. This can be managed using an automatic pump controller and automatic valve controller. - Stopping Water Flow in Case of Leakage

Use Case: If a pipe starts leaking, an automatic water shut off valve can immediately stop the flow of water, preventing water waste and potential damage. This feature is particularly useful in large systems where a single leak could cause significant issues. - Preventing Overflow When Tanks Are Full

Use Case: Overflowing tanks can be a major problem, leading to water waste and potential damage to your property. With an automatic water level control valve and water level alarm, you can stop the water flow when the tank is full, ensuring no water is wasted.

- Equal Distribution of Water to Each Tower

Use Case: In multi-story buildings, it’s crucial to ensure that water is distributed evenly to all floors. Automating the valves allows for equal distribution, ensuring that each tower receives the right amount of water without overloading the system. - Prioritizing Water Delivery to Remote Tanks

Use Case: If a tank is located far from the pump, it might struggle to receive sufficient water. By automating the valves, you can shut off other tanks temporarily to prioritize water flow to the remote tank, ensuring it fills adequately. - Stopping Water to a Particular Tank Without Shutting Down the Pump

Use Case: If a specific tank needs maintenance, you can stop water flow to that tank without having to shut down the entire pump. This is easily achieved with an automatic float valve for water tank and automatic valve controller. - Shutting Down the Supply Line to Prevent Overflow

Use Case: If your underground tank is overflowing due to excess water supply, an automatic water shut off valve can be activated to stop the water flow, preventing waste and potential flooding. - Diverting Water to a Specific Tank

Use Case: If one tank needs to be filled urgently, valve automation allows you to divert water from other tanks to prioritize filling the critical tank. - Implementing Different Automation Policies for Different Tanks

Use Case: Even if all your tanks are supplied by the same pump, valve automation allows you to implement different automation policies for each tank. For instance, one tank might have a higher priority during peak hours, while another might be prioritized during off-peak hours.

Conclusion

Automating your valves can significantly enhance the efficiency and effectiveness of your water management system. Whether it’s using an automatic water pump controller, automatic water level control valve, or automatic water shut off valve, the ability to control water flow precisely and in real-time opens up new possibilities for optimizing water usage, preventing waste, and ensuring the reliability of your system. By understanding the different types of valves and their potential for automation, you can tailor your water management solution to meet your specific needs, ensuring that your system operates smoothly and efficiently.

Also Read:

Chapter 1: What is Water Automation?

Chapter 2: Elements of Water Automation

Chapter 3: Problems with Traditional Water Automation

CHAPTER 4: IoT-Based Smart Water Automation and Benefits

CHAPTER 5: Choosing a Smart Water Automation Solution