CHAPTER 7: Water Automation System: Safeguards to Consider

Investing in a water automation system can revolutionize the way you manage your water resources, whether it’s for your home, business, or agricultural needs. However, with great automation comes great responsibility. Understanding the risks involved and how to mitigate them is crucial to ensuring that your system runs smoothly and effectively. Here’s a breakdown of potential risks and the safeguards you should consider.

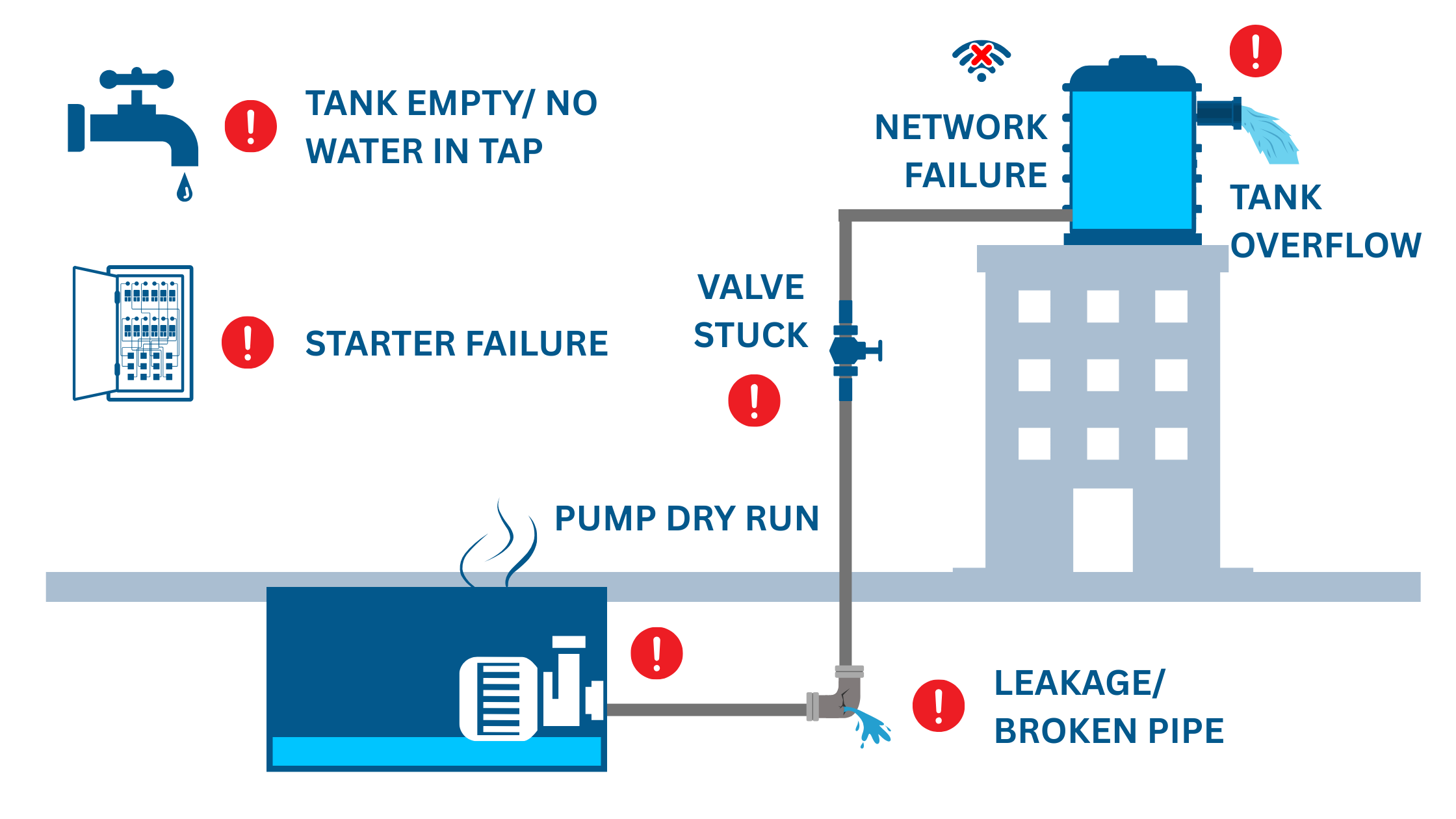

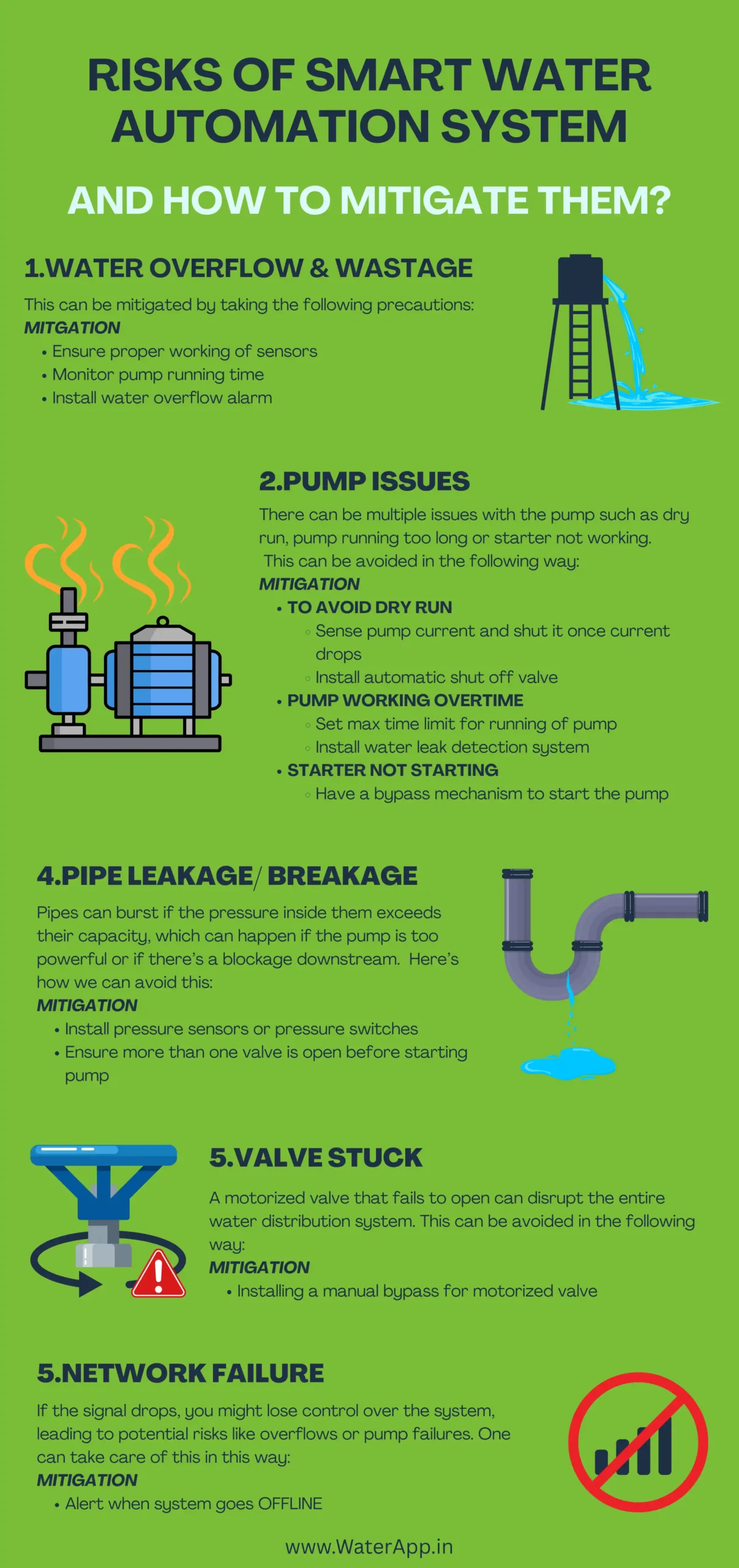

Water Overflows

Background:

Water overflows can be a nightmare, leading to water waste, property damage, and unnecessary energy consumption. This usually happens when the sensors in your automatic water pump controller or Water Level Indicator fail to detect the water levels accurately, causing the pump to continue running even after the tank is full.

Mitigation:

- Ensure Sensors Are Working Properly: Regularly check the functionality of sensors to ensure they are accurate and responsive. Consider integrating redundant sensors to act as a fail-safe if one sensor fails.

- Monitor Pump Run Time: If the pump is running longer than usual, it might be a sign of a sensor malfunction. Implement a system that alerts you or automatically stops the pump if it runs beyond the expected time frame.

- Utilize a water level alarm: Installing a water tank alarm that activates when water levels are dangerously high can provide an extra layer of protection.

Pump Dry Run

Background:

A dry run occurs when the pump operates without water, which can cause severe damage to the pump’s internal components. This situation often arises if the automatic water level control valve fails to detect the water level correctly, or if the water source has been depleted.

Mitigation:

- Sense Pump Current: Use sensors to monitor the pump’s electrical current. A sudden drop in current can indicate that the pump is running dry. The system should be designed to automatically stop the pump when this is detected.

- Install an automatic water shut-off valve: This can be programmed to stop the water flow to the tank in the event of a dry run, protecting the pump from damage.

Pump Running for Too Long

Background:

Prolonged pump operation can lead to overheating and increased wear and tear, shortening the lifespan of your equipment. This often happens when the pump continuously tries to fill a leaking tank or when there’s an undetected issue with the automatic float valve for water tank.

Mitigation:

- Use Historical Data: By analysing past data, you can determine the average running time for your pump. Set a configurable time period as the maximum allowable running time, and ensure the system stops the pump automatically after this period to prevent damage.

- Integrate water leak detection systems: If a leak is detected, the pump can be stopped automatically to prevent overworking.

Pipe Breakage Due to Too Much Pressure

Background:

Pipes can burst if the pressure inside them exceeds their capacity, which can happen if the pump is too powerful or if there’s a blockage downstream. Such breakages can cause significant damage and lead to expensive repairs.

Mitigation:

- Install Pressure Switches: Adding pressure switches in your pipes can help monitor the pressure levels continuously. If the pressure exceeds a safe threshold, the system should automatically stop the pump and open a automatic flow control valve to relieve the pressure.

- Create Pump Start Policies: Design your system so that the pump cannot start unless more than one automatic valve controller is open. This ensures that pressure doesn’t build up in the pipes unexpectedly.

Motorized Valve Not Opening

Background:

A motorized valve that fails to open can disrupt the entire water distribution system, potentially leading to overflows or dry runs, depending on the scenario.

Mitigation:

- Install a Manual Bypass: Always have a manual bypass installed for critical motorized valves. This allows you to manually control the valve in case of a malfunction, ensuring that the system remains operational even if the motorized valve fails.

Pump Not Starting

Background:

Sometimes, the pump may fail to start due to a malfunction in the starter or other electrical components. This can be particularly problematic if the pump is responsible for supplying water to critical areas.

Mitigation:

- Bypass for Pump Starter: Install a bypass for the pump starter so the pump can be started or stopped manually. This is especially important in emergency situations where automation fails.

Tank Empty

Background:

An empty tank can lead to a dry run or, in worse cases, disrupt the water supply to the entire system, causing inconvenience and potential damage.

Mitigation:

- Critical Alerts: Set up your system to present critical alerts well in advance when water levels are low. A water level indicator combined with a water level alarm can provide timely warnings, allowing you to take corrective action before the tank runs dry.

IoT Equipment Lacking Proper Network Signal

Background:

One of the challenges with IoT-based automation systems is that they rely on strong and consistent network signals to function correctly. If the signal drops, you might lose control over the system, leading to potential risks like overflows or pump failures.

Mitigation:

- Offline Alerts: Configure the system to display an appropriate message that indicates when the system is offline and needs to be monitored manually. This ensures that you remain aware of the system’s status even if the automation temporarily fails.

Conclusion

By understanding the potential risks involved in water automation systems and implementing these safeguards, you can ensure that your system operates efficiently and safely. Whether it’s using an automatic water pump controller, automatic valve controller, or water leak detection system, these measures will help you mitigate risks and maintain a reliable water management solution.

Also Read-

Chapter 1: What is Water Automation?

Chapter 2: Elements of Water Automation

Chapter 3: Problems with Traditional Water Automation

CHAPTER 4: IoT-Based Smart Water Automation and Benefits