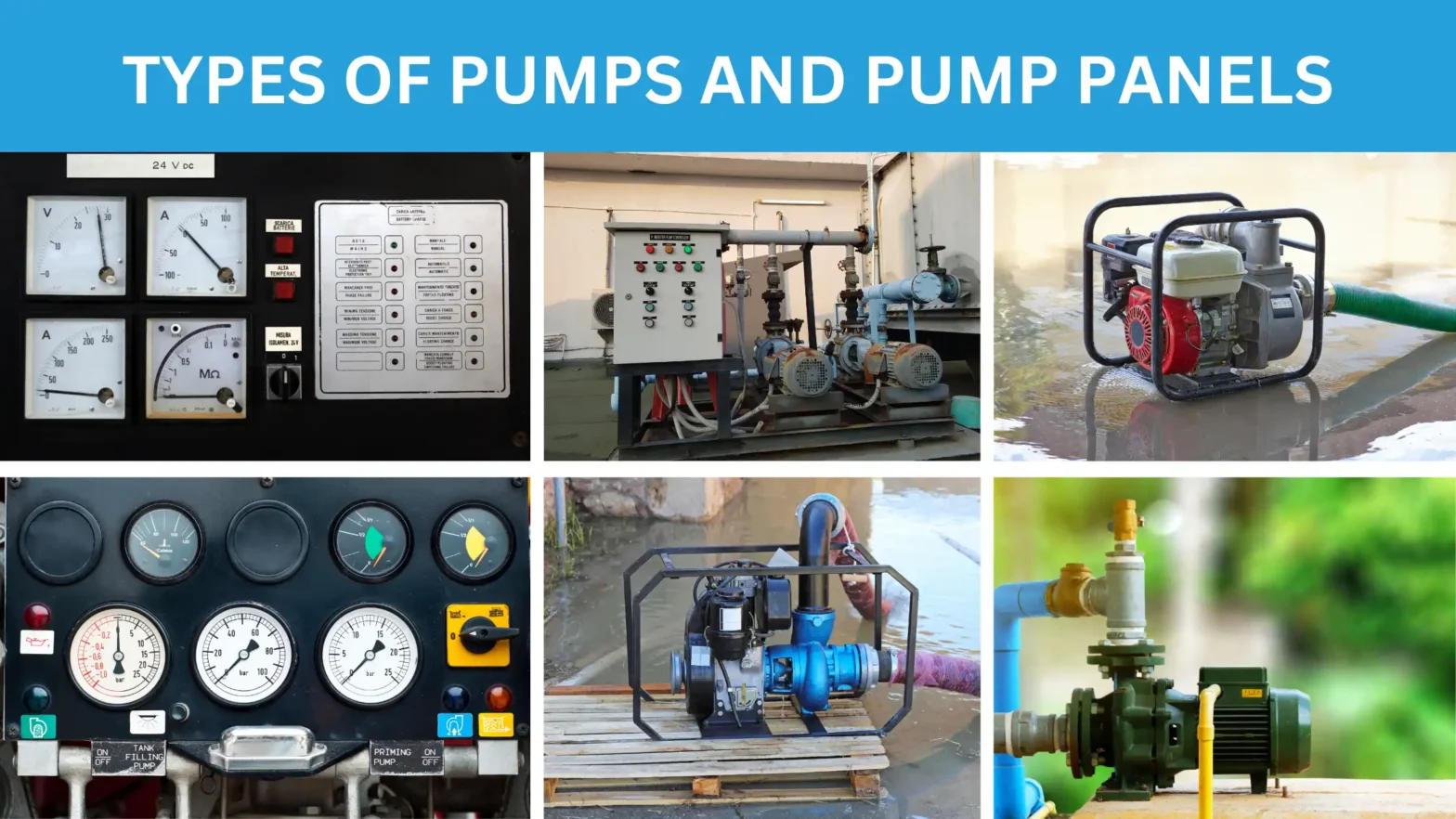

CHAPTER 6: Types of Pumps and Pump Panels

When it comes to water management, whether you’re maintaining your backyard pond or managing a sprawling industrial site, the type of pump you choose can make all the difference. Think of pumps as the heart of any water system—without them, everything comes to a standstill. So, let’s dive into the types of pumps, their components, and the best practices for choosing the right one for your needs.

Types of Pumps

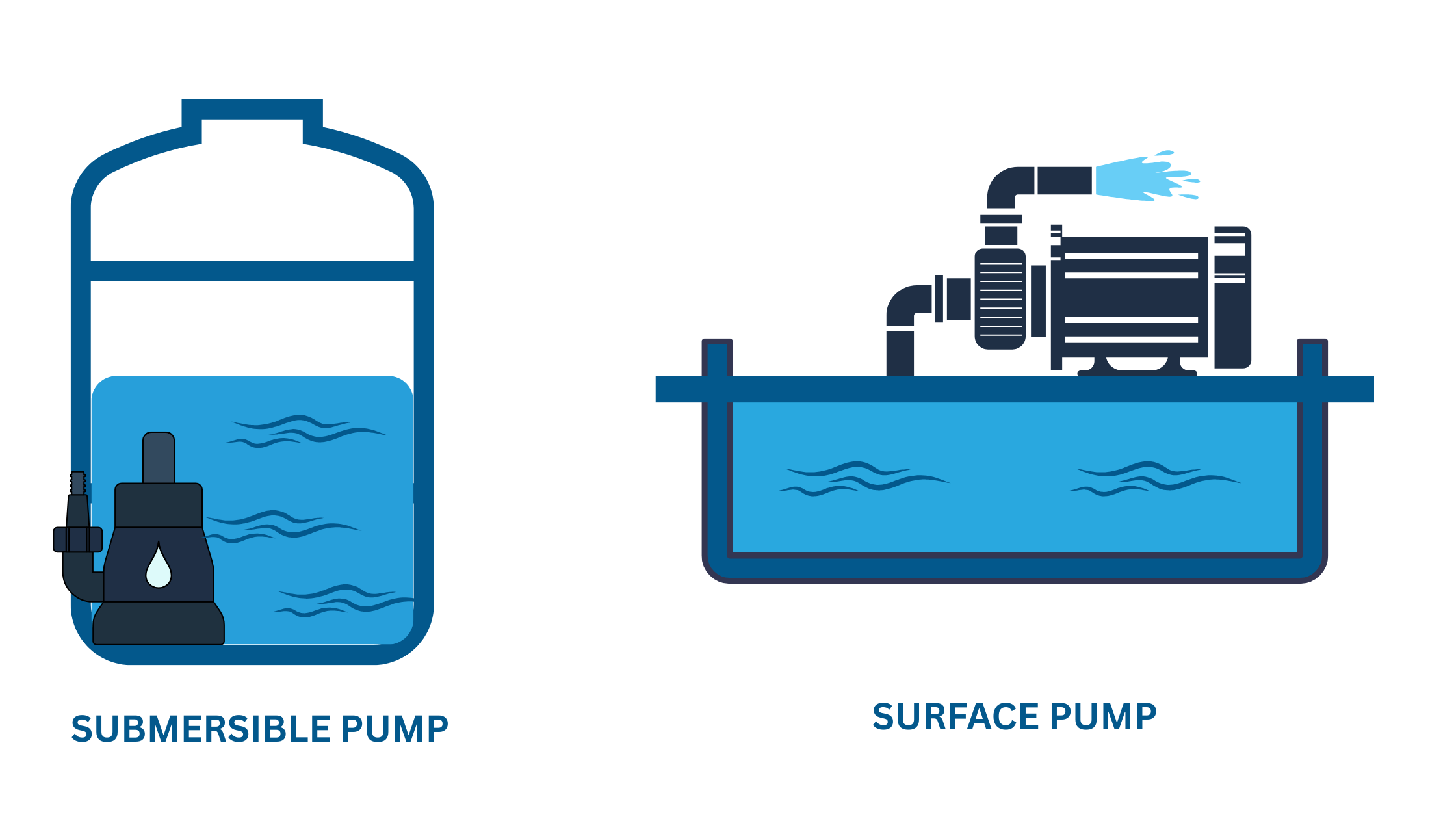

1. Surface Pumps

Surface pumps, as the name suggests, are installed above the water source. They’re the go-to choice for shallow wells, ponds, or any water source that’s not too deep. Think of them as the overachievers who always want to stay dry, yet still do all the heavy lifting.

Pros:

- Easy Maintenance: Because they’re not submerged, accessing and maintaining these pumps is a breeze. If you’re the kind of person who likes to keep an eye on things, this is your type of pump.

- Cost-Effective: Generally, surface pumps are less expensive upfront compared to their submersible counterparts.

Cons:

- Limited Depth: Surface pumps struggle with water sources that are more than 25 feet deep. It’s like trying to suck a thick milkshake through a tiny straw—it just doesn’t work well.

- Noise: They tend to be noisier since they operate out in the open. So if you prefer peace and quiet, this might be a drawback.

When to Use: Surface pumps are ideal for shallow wells, irrigation systems, or anywhere you have easy access to the water source and don’t mind a bit of noise.

2. Submersible Pumps

Submersible pumps, on the other hand, like to dive right into the action—literally. These pumps are submerged in the water source, making them the perfect choice for deep wells, sump systems, and even sewage treatment.

Pros:

- High Efficiency: Being submerged means they are constantly surrounded by water, which helps cool the motor and improves efficiency. Plus, no priming is required since they’re always in contact with the water.

- Quiet Operation: Because they operate underwater, you won’t hear much from them—perfect if you’re not a fan of noisy machinery.

Cons:

- Maintenance Challenges: Since they’re underwater, accessing them for maintenance can be tricky. It’s a bit like trying to fix a leak on a submarine—you need the right tools and expertise.

- Corrosion Risks: Being constantly submerged means these pumps are more prone to corrosion, especially in harsh environments. You’ll want to ensure they’re made from corrosion-resistant materials.

When to Use: Submersible pumps are your best bet for deep wells, sump systems, and applications where noise reduction is important, such as residential settings.

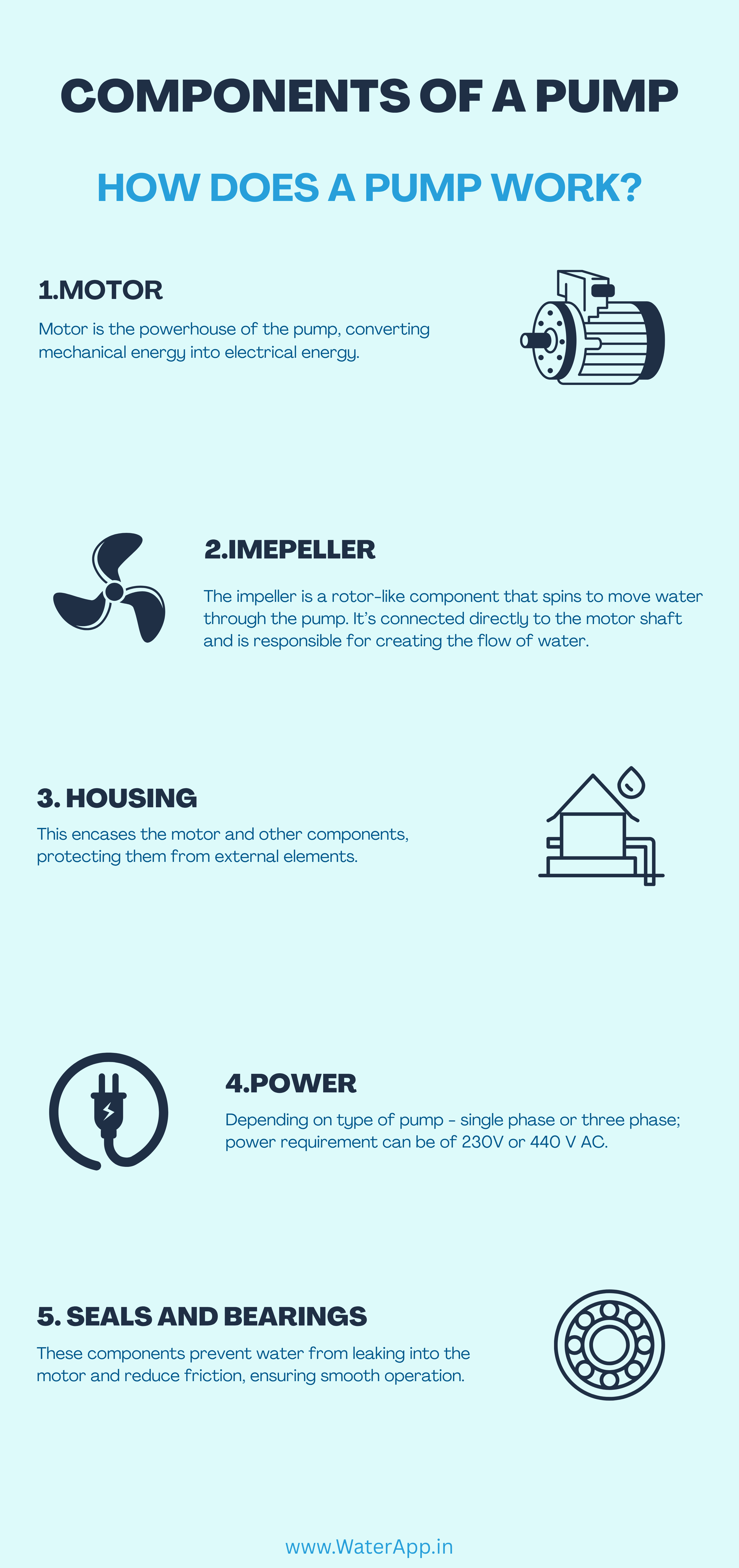

Components of a Pump

Understanding the components of a pump can help you better maintain and troubleshoot it, ensuring long-term reliability:

- Motor:

The motor is the powerhouse of the pump, converting electrical energy into mechanical energy. In submersible pumps, the motor is hermetically sealed to prevent water ingress, which is crucial for underwater operation. - Impeller:

The impeller is a rotor-like component that spins to move water through the pump. It’s connected directly to the motor shaft and is responsible for creating the flow of water. The design of the impeller can vary based on the type of fluid being pumped, whether it’s clear water or something more viscous like sewage. - Pump Housing:

This encases the motor and other components, protecting them from external elements. For submersible pumps, the housing is usually made from corrosion-resistant materials to withstand prolonged exposure to water. - Seals and Bearings:

These components prevent water from leaking into the motor and reduce friction, ensuring smooth operation. Regular inspection of seals and bearings is crucial to prevent premature wear and tear.

Types of Starters

1. DOL (Direct On Line) Starter:

The DOL starter is the most straightforward type of motor starter, applying full line voltage directly to the motor terminals. It’s like flipping a light switch—the motor either runs at full speed or it doesn’t run at all.

Pros:

- Simplicity: Easy to use and maintain, making it ideal for small motors.

- Cost-Effective: Generally cheaper than other types of starters.

Cons:

- High Inrush Current: Can cause a significant surge in current, which might strain your electrical system.

When to Use: Best for small motors where cost and simplicity are key considerations.

2. Star/Delta Starter:

The Star/Delta starter is a bit more sophisticated. It starts the motor in a low-voltage “star” configuration before switching to the full-voltage “delta” configuration. This method reduces the initial inrush current.

Pros:

- Reduced Inrush Current: Helps protect your electrical system by limiting the surge of current at startup.

- Better for Large Motors: Ideal for larger motors that require a gentler start.

Cons:

- Complexity: More components and wiring make this starter more complex and potentially more expensive to maintain.

When to Use: Suitable for large motors where reducing the inrush current is critical to prevent damage to the electrical system.

Conclusion

Choosing the right pump and pump panel is like selecting the right tool for the job—it’s all about understanding your needs and the environment in which the pump will operate. Whether you go for a surface pump or a submersible one, understanding the pros and cons of each, along with the components and starters that drive them, will ensure you make an informed decision. So next time you’re faced with the daunting task of selecting a pump, you’ll be armed with the knowledge to pick the perfect one for your needs.

Also Read:

Chapter 1: What is Water Automation?

Chapter 2: Elements of Water Automation

Chapter 3: Problems with Traditional Water Automation